Dr. Pero Mićić

The humanoid robots are coming!

They will have amazing physical skills and they are also becoming intelligent. I’m not exaggerating: if they succeed, it will be the biggest technological revolution and disruption in human history.

But will companies and people even be able to afford their work? If they turn out to be too expensive, then the optimistic visions cannot be achieved. How much will a humanoid’s working hour cost? You’ll get the answer in this article.

This is the fourth episode in my series on humanoid robots. If I summarize the first three episodes, it sounds like this:

- Humanoid robots can already perform many, soon most and in the long term all physical activities of humans.

- Humanoid robots will have an AI brain. This will make them cognitively intelligent. This means that they will be able to think and find solutions that they have not been taught directly.

- Humanoid robots will learn new skills at an enormous speed. In fact, the pace of learning will increase exponentially. We humans have no chance of learning new skills so quickly.

People of course need a good income, of course. In the future, however, we will derive our income less and less from work as we have understood it up to now. More on this in an upcoming episode.

Which jobs will humanoid robots do?

Okay, so humanoid robots are becoming universal working machines. What jobs are we actually talking about? For example, work in logistics, i.e. the handling and transportation of goods. Work on production lines. Gardening and landscaping. Construction site work, hospitality services, nursing care, senior services, security personnel. Yes, later also in the trades as tilers, electricians or plumbers.

How much will humanoid robots cost?

What do we need to know or estimate to answer this question? First of all the manufacturing costs. At the moment, there is only one humanoid robot for sale. It is the small Alpha 1 Pro from Unitree in China. It costs around USD16,000.

It can’t do much yet. Rather hardly anything. The larger H1 is said to cost USD90,000.

However, this is only a first small series. What is more important is how much such a humanoid robot will cost when they are produced in large numbers.

This is where the experience curve, or “Wright’s Law”, is helpful. With each cumulative doubling of the number of units produced, the costs fall by a constant factor.

For lithium-ion batteries, costs have fallen by an average of 15-20% since 2012. With every cumulative doubling of production. From 100 to 200 to 400 to 800 to 1600 etc.

In the case of electric cars, also a relatively new product category whose production is therefore rapidly doubling, manufacturing costs have fallen by over 25% with each cumulative doubling of production.

Let’s stick with the analogy of an electric car. Humanoid robots are smaller, so they need less material. The actuators and motors are the most expensive parts, along with the battery and the electronics. These are all parts that can be mass-produced and are therefore becoming cheaper according to Wright’s law.

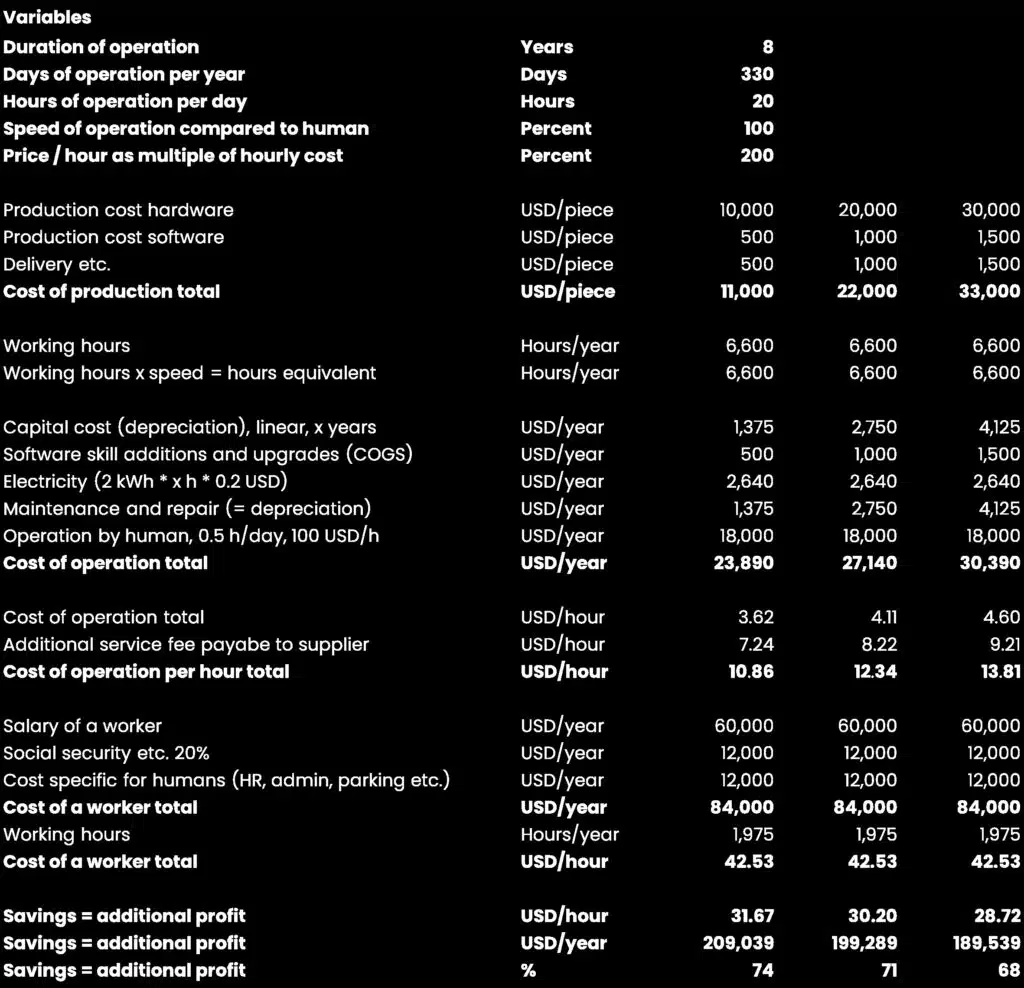

Let’s assume manufacturing costs of USD30,000 per HR for 2030 despite these expected cost reduction effects. Let’s assume that manufacturing costs will fall to USD10,000 per unit by 2040. Let’s add 1,500 for the provision of the software and the same amount for delivery, etc. These costs will also fall per unit. At least for the manufacturers. Then we arrive at total manufacturing costs of 33,000 in 2030, later 22,000 and 11,000 Dollars.

How many hours can humanoid robots work per year?

Humanoid robots don’t need a vacation and they can be repaired or replaced very quickly when they are damaged. They won’t go on strike either. A CNC machine can run about 90% of the maximum time. That would be around 330 days per year. Realistically, we will use this value for an HR, too.

How many days a week can an HR work? Obviously, all seven days of the week.

How many hours a day? Theoretically 24 hours. But if we assume that an HR also has to be maintained or realigned every day, we can deduct an hour. And let’s assume that not every HR can be charged inductively via the floor on which it stands. It must have its battery replaced or be charged for an hour. We also deduct an hour for charging.

If we subtract another two hours from the remaining 22 hours to be on the safe side, we end up with 20 working hours per day. Again, a rather pessimistic assumption.

330 days times 20 hours equals 6,600 working hours per year.

How fast will humanoid robots work?

At the moment, humanoid robots move slower than humans in every respect. But the speed of work will continue to increase. Modern industrial robots can now work at two and a half times the speed of humans.

It is therefore rather cautious, and again pessimistic, to assume that humanoid robots in 2030 will be able to work at the same speed as humans. In other words, 100%. In the long term, it is more likely to be 200% or more.

For how many years will a humanoid robot last?

A car is used for around 20 years. A lathe or milling machine and even a CNC machining center can be used for around 10-15 years. At least. Let’s remain cautious and assume only eight years for the humanoid robot, also due to the very rapid technological progress at the beginning. After eight years it is scrap and will be recycled. This is a rather pessimistic assumption. Because very old robots can still be used, even if they have lower physical skills than newer models.

What high are the capital costs?

The capital costs per year are USD 4,124. That is the purchase price divided by the operating years. I estimate the pure purchase price for new skills, at USD 1,500 per year. In reality, manufacturers will charge much more for the skills. We’ll look at that later.

How high are the energy costs?

With very hard physical work, a human worker consumes 500 to 800 kilocalories per hour. For light physical work, it is 100 to 300 kilocalories. Let’s take the rather high number of 600 kilocalories per hour as an average. Each kilocalorie is calculated as 1.162 watt hours. In other words, around 0.7 kWh per hour of hard physical work by a person.

Humans are amazingly energy efficient. That’s why we use three times this value for hard work by an HR.

That is approximately 2 kWh of energy per hour of work. That would be 40 kWh per day. As I said, this is a very high number. Most of the work done by an HR will require significantly less energy.

And now let’s take a rather high industrial electricity price of USD0.20 per kWh. That means energy costs of USD8 per day or USD2,640 per year.

What are the costs for maintenance and repair?

For this we can simply assume that maintenance and repairs cost so much that we have to pay the production costs of the HR again during the 8-year service life. In other words, USD4,125 per year.

What are the costs for the people who operate humanoid robots?

The robots will not be able to work entirely without people. People will always have to intervene, if only to deploy the HR in the right place with the right function. This will cost human time and therefore money. However, it won’t be much time for each individual robot.

We assume half an hour per day per HR and value it at USD100 per hour, effectively USD50 per half hour and therefore USD18,000 per year. Isn’t it interesting that the biggest cost driver for operating the robot is the remaining human labor?

So we have a total of USD30,390 in operating costs per year and USD4.60 per hour. Initially. Then less and less later on.

How much do you really have to pay the robot manufacturer?

We assume that the manufacturers will not sell their humanoid robots. They will apply the Robot as a Service business model. In other words, they will lease out their robots. Anyone who wants to use an HR will – we assume – have to pay an amount per working hour.

Why is that? Because such a model has many advantages. The customer only pays for the service they actually receive. The manufacturer can rule out the possibility of robots being used for illegal purposes. Above all, the manufacturer can earn several times more per robot with RaaS than if he simply sells the robots.

As we will see later, a single humanoid robot saves a huge amount of money per hour and year. The robot manufacturers will want a large share of this. Under no circumstances will they simply add a standard profit margin to the costs.

They will charge what customers are prepared to pay.

If you can save 30 USD per hour with a product, you are not only willing to pay 5 USD per hour, but rather 10 USD or even more. Because you save much more than you pay.

We assume that manufacturers will charge three times their production costs. So we apply a multiplier of 200% for this. This includes software updates and upgrades.

Another USD 9.21 is then added to USD 4.60, so that the working hour initially costs USD 13.81 and later USD 10.86.

It should be noted that we have used quite high values at every point of the estimation so far and still come up with fairly low costs.

What is the cost of human labor per hour?

A skilled worker in Germany receives a gross salary of less than 20 USD per hour. I don’t think that’s enough. But that’s another topic. That would be around 45,500 USD per year for full-time work, including payments for vacation, public holidays and sick leave.

With thirteen salaries per year, it would be around 50,000 USD. In the USA, salaries are significantly higher. To be on the safe side, let’s assume USD 60,000 gross per year.

For the social costs in Germany, i.e. pension contributions and insurance for sickness, unemployment and accidents, company doctor, etc., we assume 20%, i.e. USD 12,000 per year. This amount is too high for the USA and too low for Germany.

Employees have to be found and recruited in the first place. Recruitment costs are therefore incurred for each employee. The cost of purchasing a robot, however, which can also be used for all kinds of tasks, is significantly lower. In addition, employees need to be supervised, led, managed and administered. Much more than a robot.

Employees need social areas, parking spaces and so on. And above all, employees have to be trained for each job. With a humanoid robot, you simply install a new skill and that’s it. Let’s assume only 20% additional costs for all this, which is quite low.

With a gross salary of USD 60,000, we arrive at a total cost of USD 84,000.

If we now take the average value of annual working hours in Germany and the USA, we arrive at 1,975 hours per employee per year. That is a cost per working hour of USD42.53.

How much does a humanoid robot cost per working hour?

Per working hour, the costs for humanoid robots are therefore around 68 to 74 percent lower. USD 28.72 lower and later up to USD 31.67 lower. Multiplied by the number of working hours of an HR, the total savings per humanoid robot are USD 190,000 initially and USD 209,000 later, per year! Even under very conservative assumptions.

Humanoid robots will cost around 25 to 30% as much per working hour as a human. If we double the working speed of humanoid robots, they will only cost 13 to 16% of a human employee per hour. Companies will have no choice but to use humanoid robots to compete.

And now?

In the first three articles, we have established that the physical capabilities of humanoids will very quickly reach and then surpass those of humans. That the cognitive skills will also be very high thanks to the integration of AI. And that the abilities of humanoids will also grow very quickly because they can learn new skills in an amazingly simple and fast way. Namely by observing humans, watching videos or even by self-learning.

Now we can also say that they will also be much cheaper than human employees. This will massively change the world of work and life. Humanoid robots will find their way into our working and living environments faster than most people can imagine today.

How many of them will work for us? We have 1.5 billion cars on the planet. In the not too distant future, 20 or 30 years maybe, we will see a similar number of humanoid robots working for us. We will have to and we may rethink work and income in a completely new way. We humans will reinvent our understanding of the meaning of life.

In the three previous episodes, I recommended that you include humanoid robots in your strategic analyses and considerations. You will have to reinvent your job and your company sooner than you intuitively think.

And don’t forget: Humanoid robots and all the products and services around them will be one of the biggest, if not the biggest growth market of the future. Please check how you can participate and contribute with your company.

You need a new strategy for the future. We are happy to help.

If you want regular practical tips and strategies for your foresight and strategy, free of charge, become a member of our “Bright Future Leaders” community.

Take a look at all the episodes on robotics here:

– Humanoid robots: the solution to the labor shortage? (Part 1)

– Humanoid robots: will they be intelligent enough? (Part 2)

– Humanoid robots: how will they learn? (Part 3)

– AI kills all jobs – and then what?

Three scenarios (Part 1)

– Prosperity through AI, but how? (Part 2)

Have a bright future!

Placeholder